Modern engineering relies on accuracy. Every cut, movement, and alignment must meet exact specifications. At the heart of many advanced systems lies a simple yet powerful component—the ball screw. Among the finest in this category is the BLR Ball Screw (บอลสกรู blr, which is the term in Thai), known for driving precision in machines across industries.

The Role of Ball Screws in Precision Engineering

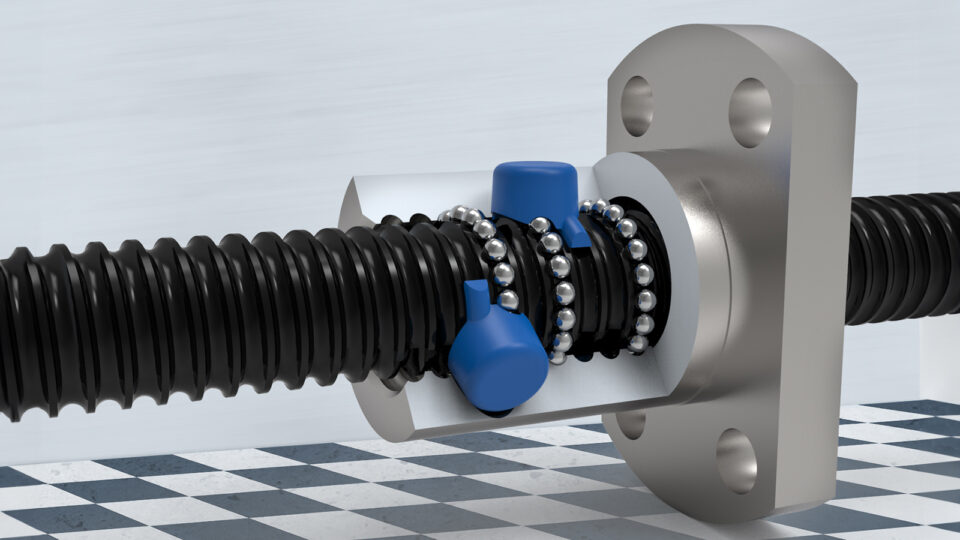

Ball screws convert rotational motion into linear motion with minimal friction. Their design reduces heat build-up and wear, ensuring longer life and reliable output. Engineers favour them for applications where even a fraction of an error could lead to costly mistakes.

From CNC machines and robotics to aerospace and automotive systems, ball screws guarantee smooth, accurate, and repeatable movements. This is why they remain central to modern production lines where consistency is key.

Why BLR Ball Screws Stand Out

The BLR series is engineered with durability and high efficiency in mind. The design features hardened steel tracks and recirculating ball bearings that support heavy loads while maintaining low resistance. This results in:

- High positioning accuracy with minimal backlash.

- Greater load-bearing capacity without compromising speed.

- Reduced maintenance needs, saving both time and cost.

For sectors like aerospace, medical technology, and advanced manufacturing, BLR ball screws provide the stability and reliability needed to meet global standards.

Applications Across Industries

The versatility of BLR ball screws makes them indispensable.

- Robotics – Smooth motion ensures controlled articulation of robotic arms.

- Aerospace – They enable safe, accurate actuation in high-stakes environments.

- Automotive – Used in steering and testing equipment to meet exact tolerances.

- Industrial Machinery – Essential in CNC machines for cutting, milling, and drilling operations.

Every sector that values precision finds an ally in this compact yet powerful mechanism.

I.N.B. Enterprise: Delivering Quality Engineering Solutions

I.N.B. Enterprise has built a reputation as a trusted supplier of engineering components. The company provides world-class products that meet the growing demands of advanced industries. Their catalogue includes premium ball screws, linear guides, and other motion-control systems designed for performance and longevity. With a focus on customer needs and strict quality standards, I.N.B. Enterprise ensures businesses gain reliable components that power progress. I.N.B. Enterprise is a valued partner for organisations that seek innovation and trust.

The Future of Precision Engineering

As industries move towards automation and smart manufacturing, the demand for reliable motion-control components continues to grow. BLR ball screws are likely to remain a cornerstone, adapting to new technologies while delivering proven performance. Their ability to merge strength, speed, and accuracy will power the next generation of engineering breakthroughs.

In summary

BLR ball screws are not just mechanical parts; they are precision enablers. They have become indispensable in today’s engineering world by reducing friction, enhancing accuracy, and supporting advanced applications. With companies like I.N.B. Enterprise supplying these high-quality solutions, the future of precision engineering looks secure and promising.